Crossrail created over 7 million tonnes of waste material from the various construction sites across the 42km of tunnels created for the project. Crossrail, had a construction strategy with a target to move at least 45% of material using rail and water. As a result of the drive to use rail and water to transport as much of the material as possible, the Port of Tilbury was selected as a transfer site in the Crossrail project.

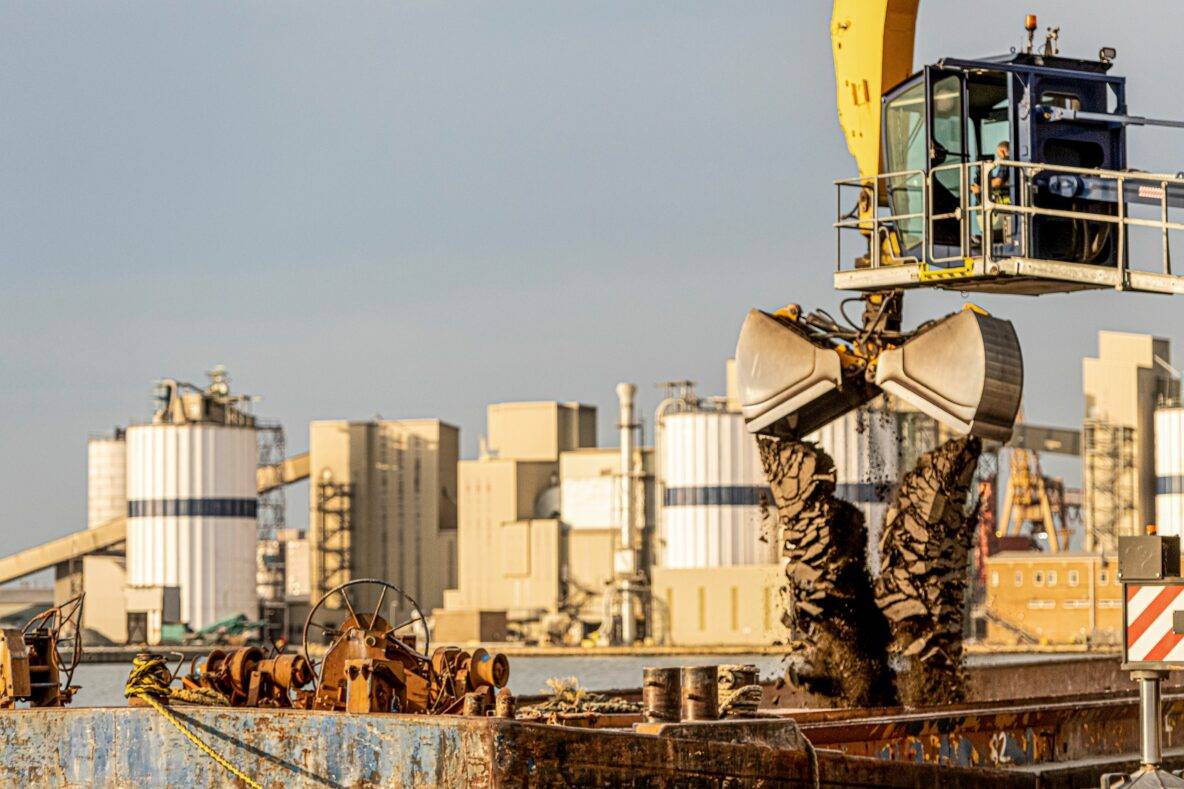

During construction, S. W. Walsh & Sons removed construction waste from tunnelling sites via barge, using the river as an alternative transportation method, before the Port of Tilbury, received and offloaded the spoil using our equipment on site.

The construction waste was then processed, washed and stockpiled on site by S. W. Walsh & Sons at the Port of Tilbury before it was re-loaded by the Port onto barge for onwards transport to Wallasea Island RSPB nature reserve to be used in coastal habitat restoration.

The Port of Tilbury also assisted in the handling and transport of two 800 tonne, 76 metre pontoons used to create a temporary jetty at Wallasea Island – which if not installed, would have resulted in Wallasea Island being unable to receive the materials handled at Tilbury via the water.

Upon completion of the project, around 3 million of the 7 million tonnes of material generated by the project was used at Wallasea Island, and across the entire programme, 80% was transported by water or rail when evaluated on a km/tonne basis.

The Port of Tilbury was able to play a key role in facilitating the transportation of materials onwards to Wallasea Island, which helped the Crossrail project achieve its targets for alternative transport use, and helped create one of the largest wildlife habitats in Western Europe.